Selecting a high-quality power tiller gearbox is crucial for efficiently converting engine power, enhancing work efficiency, and improving stability.

The shaft-driven power tiller gearbox offers more direct power transmission, enhanced machine performance, and higher speed. We provide different configurations based on customer usage conditions to ensure optimal performance for our clients.

The power tiller gearbox is designed to convert the high-speed, low-torque power produced by the engine into low-speed, high-torque power. Different gear configurations are suited for various applications. Using high-precision gears can enhance work efficiency, and an appropriate speed ratio can help reduce the fuel consumption of the engine.

Our Products

Power Tiller Gearbox Manufacturing Processes

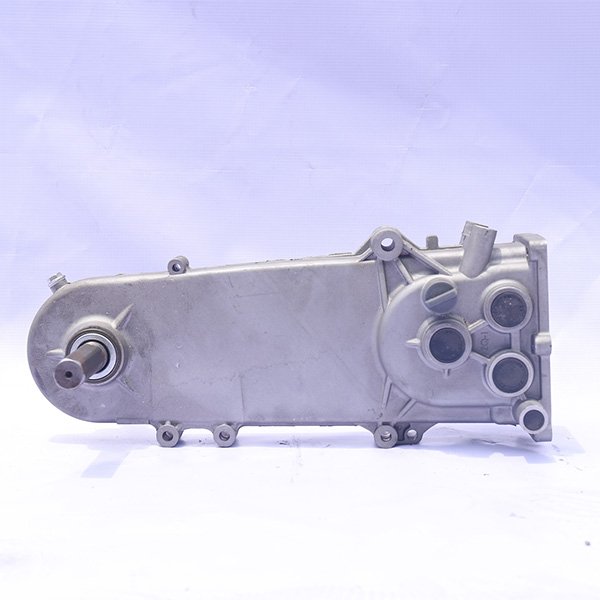

The YINCHOU power tiller gearbox features low speed and high torque, optimized modulus, and tooth shape for effective soil crushing. It includes a double-lip skeleton oil seal, an O-ring for superior sealing, and a maze-type dustproof groove to keep out mud and water. Components are precision-machined with CNC technology, and a carburizing and quenching process enhances surface hardness and core toughness.

Gearbox structural features

The full gear transmission system is designed for both dry land and paddy field cultivation, featuring gear configurations of 3F1R or 2F1R for varied speed options. The power tiller gearbox includes a double differential, dual steering control for easy turning, and a shaft transmission box driven by two bevel gears for improved efficiency.

Multifunctional Adaptation

Engines with 5-15 hp from different brands can be adapted to our mini tiller gearbox. The output spline shaft is compatible with rotary blades, weeding blades, ridgers, trimming blades, and other agricultural tools.

Raw material suppliers undergo a thorough screening process and must provide relevant material certificates and test reports. Upon arrival, incoming raw materials are either sampled or fully inspected. We utilize CNC machine tools and machining centers for processing, and each step in the process adheres to strict specifications and testing requirements. If any deviations occur, adjustments can be made promptly.Actually, not only for the gearbox, all our other power tiller parts are under the same quality control.

The double lip oil seal, combined with a labyrinth groove and an oil ring, enables the lubricating oil to flow back into the power tiller gearbox, preventing leaks through gaps. However, it is normal for a small amount of oil to escape from the gearbox breathble screw. The vent is designed to balance the internal pressure and release heat generated during operation.

The power tiller gearbox should be filled with antifreeze oil or gear oil. Change the transmission gear oil annually or every 500 hours, and refill it. Before replacing, open the oil drain valve to allow the old oil to flow out.