Agricultural production in the Central Asian region (represented by Uzbekistan) is dominated by small plots of cultivated land, with widely distributed complex terrains such as hills and mountains. The main crops grown are cotton, wheat, vegetables, etc. This agricultural pattern puts forward core requirements for small 170F Gasoline Motor Cultivators, including light weight, flexibility, and low energy consumption. With its precise technical positioning and market-adapted design, the Model 170F Gasoline Motor Cultivator not only fills the application gap of 170F Gasoline Motor Cultivators in a specific power segment but also becomes an ideal equipment to help Central Asian farmers improve agricultural efficiency and reduce labor intensity with its core advantages of “high-efficiency adaptation, high cost-performance ratio, and high durability”. This article will comprehensively analyze the market value of the Model 170 170F Gasoline Motor Cultivator from the dimensions of core product characteristics, technical advantages, application scenarios, special adaptation to the Central Asian market, and upgrade directions.

Core Parameters and Structural Design: Laying a Solid Foundation for Adaptation

Taking “precise matching of small plot cultivation operations” as the core design concept, the Model 170 170F Gasoline Motor Cultivator forms systematic advantages in power, transmission, cultivation, and overall machine characteristics. Its key parameters and structural design are in line with the actual agricultural production needs in Central Asia

Power System: High Efficiency, Low Consumption, and Convenient Startup

Equipped with a 170 gasoline engine, its core parameters have excellent practical performance: displacement 208ml, maximum output power 5.1kW, rated speed 3600rpm, fuel consumption rate as low as 395g/kw·h, balancing operational power and fuel economy; the startup method supports both manual pulling and electric starting. Among them, the electric starting mode greatly reduces the operation threshold for middle-aged and elderly farmers, adapting to the characteristics of the rural labor structure in Central Asia. The fuel tank capacity is 3.6L, which can meet the needs of long-term continuous operations, fitting the scenario of scattered plots and non-concentrated operation points in Central Asia.

Transmission System: Stable, Efficient, and Flexible Operation

Adopting a gear transmission gearbox, it has high transmission efficiency and stable operation, with lower maintenance costs compared to chain transmission; the gear setting is scientific, equipped with multiple forward and reverse gears, and the operating speed can be flexibly adjusted between 0.1~0.3m/s, adapting to the cultivation needs of different crops. The main clutch adopts a manual safety clutch design, with sensitive operation response, improving operational safety.

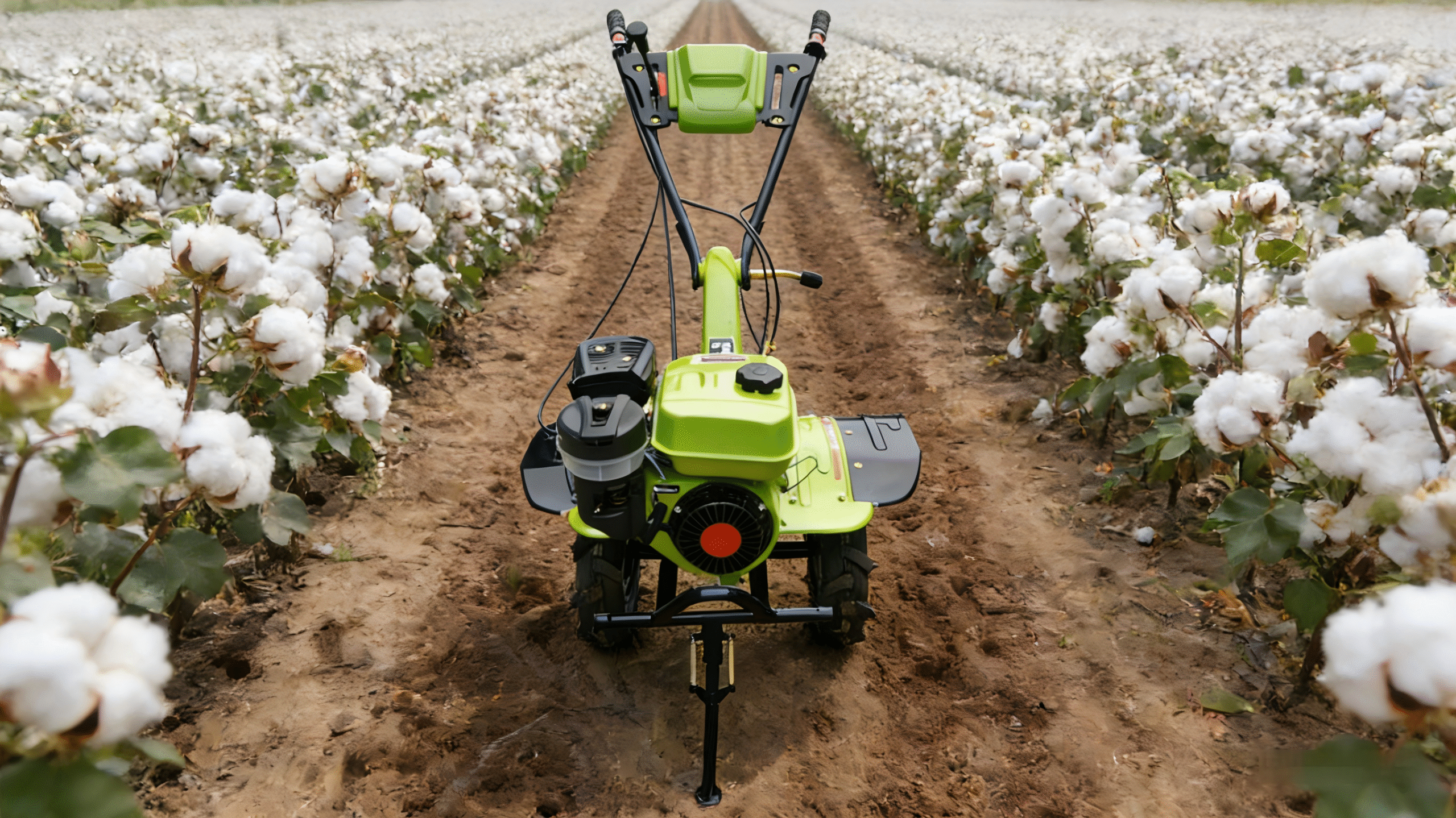

170F Gasoline Motor Cultivator

170F Gasoline Cultivator: Multi-functional Adaptation and Convenient Disassembly

The cultivation width ranges from 75-100cm, and the cultivation depth is ≥10cm, which can be flexibly adjusted according to the planting needs of different crops such as cotton, wheat, and vegetables; it is equipped with two types of cutter shafts: rotary tiller blades and weeding blades, with a total of 24 170F Gasoline Motor Cultivator blades installed on the cutter shaft, adapting to the whole-process operations from land reclamation to field management; it adopts a quick-detachment connection method, allowing farmers to easily replace the blades and improve operation efficiency.

170F Gasoline Motor Cultivator: Lightweight Design, Durable and Easy to Operate

The overall weight is controlled at 60-81kg, and the overall dimensions are approximately 1460×620×750mm. The lightweight design is convenient for manual handling, perfectly adapting to the transfer needs of small plots such as hills and mountains in Central Asia; the armrest supports multi-angle adjustment in horizontal and vertical directions, with an adjustment range of up to 180 degrees, flexible steering, and farmers of different heights can operate comfortably; the 170F Gasoline Motor Cultivator body is made of carbon steel and alloy materials, balancing rigidity and wear resistance, and extending the service life.

170F Gasoline Motor Cultivator Technical Advantage: Highlighting Differentiated Core Value

Through multi-dimensional comparison with competitors in the same power segment and electric 170F Gasoline Motor Cultivators, the core advantages of the Model 170 170F Gasoline Motor Cultivator are more prominent, accurately matching the usage scenarios and conditional constraints of the Central Asian market

Significant Balanced Advantage. Compared with competitors in the same power segment such as 168F and 178F, the biggest advantage of the Model 170 170F Gasoline Motor Cultivator is the realization of a “golden balance of power-fuel consumption-weight”. Data shows that the fuel consumption per unit operating area of the 168F model is about 3.16 kg/mu, and the overall weight of the 178F model reaches 115kg, while the fuel consumption rate of the Model 170 is as low as 30kg/hm² (about 2 kg/mu), and the weight is 47% lighter than that of the 178F. At the same time, the power maintains a practical level of 5.1kW, which greatly reduces the farmers’ fuel costs and handling burden on the premise of ensuring operation efficiency. In addition, the Model 170 has more advantages in manufacturing costs, with a lower price on the premise of meeting power standards, showing obvious cost-performance advantages.

Adaptation to Complex Working Conditions

In view of the aging rural power infrastructure, poor power supply stability, and lack of power coverage in remote areas in Central Asia, the Model 170F Gasoline Motor Cultivator shows irreplaceable advantages compared with electric 170F Gasoline Motor Cultivators. On the one hand, gasoline models do not rely on power sources, have unlimited battery life, and can meet the needs of all-day continuous operations; on the other hand, the absence of power constraints enables them to flexibly adapt to complex terrains such as hills and mountains, while electric 170F Gasoline Motor Cultivators are difficult to cover such scenarios due to battery life and power constraints. At the same time, the power output of gasoline engines is more stable, and the cultivation efficiency and depth are more guaranteed when facing the hard soil of small plots in Central Asia.

For core crop types in Central Asia, the Model 170 gasoline motor cultivator can achieve full-cycle adaptation: in vegetable greenhouses, its lightweight and small-size design can flexibly move around to complete fine cultivation such as soil loosening and weeding; in the seedling stages of wheat and cotton, weeding blades can be replaced for seedling management to avoid damaging young seedlings; in orchard planting areas, it can complete weeding and soil loosening operations to improve soil air permeability; at the same time, its strong cultivation capacity can meet the reclamation needs of small plots, laying the foundation for the planting of new plots.